Padding Machines

SUPERIOR's SP Padding Machine line features a full range of sizes from the SP-150, accommodating small padding operations to the gargantuan SP-450 with a screen size of 90 sq. ft. These are the padders of choice in the pipeline and renewables industries.

Models

Features

SP-150

Roll over the red circles to view features.

Reversible Conveyor

Can be used on either side of machine and folds into 2 parts for ease of shipping.

Adjustable Sections

The escalator and screens sections can be adjusted for different terrain gradients.

Insulated Engine

Engine compartment reduces noise to comply with EU noise limit requirements.

Remote Control

Each movement is controlled by 10 levers. Tracks levers can maintain their position.

Optional ROPS

A ROPS is available to protect the operator when travel on the machine is required.

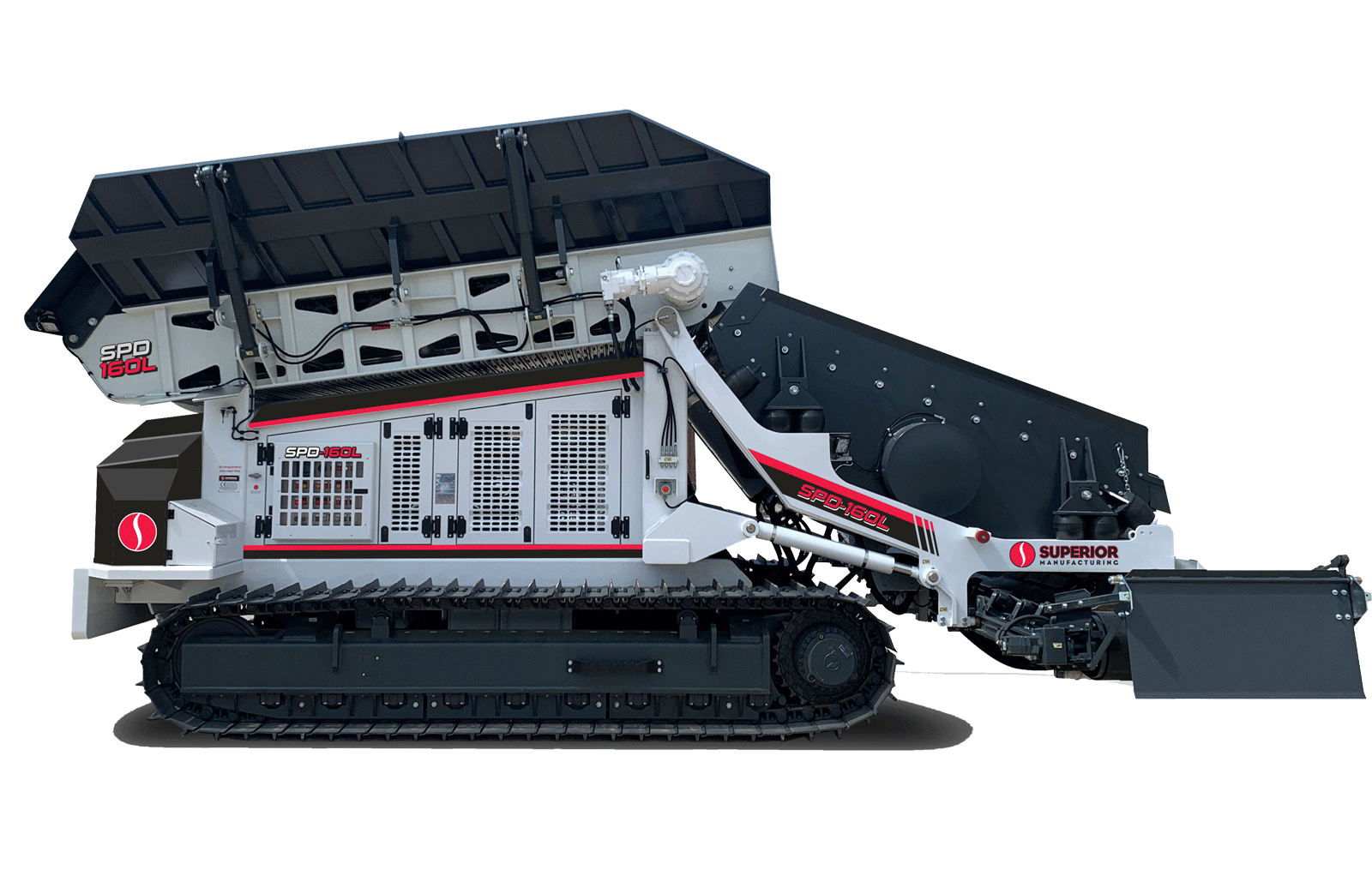

SP-160L

Features

Roll over the red circles to view features.

Reversible Conveyor

Can be used on either side of machine and folds into 2 parts for ease of shipping.

Remote Control

Each movement is controlled by 10 levers. Tracks levers can maintain their position.

Self-propelled

Unlike similar machines of its kind, the SPD-160 doesn’t require towing, as it can travel on its own.

Insulated Engine

Engine compartment reduces noise to comply with EU noise limit requirements.

Top-Loading Feeding System

Allows an excavator to feed material into the padder when very sticky soil or where maneuverability is limited.

SP-250

Features

Roll over the red circles to view features.

Reversible Conveyor

Can be used on either side of machine and folds into 3 parts for ease of shipping.

A hydraulically-controlled dowel adjusts the angle and distance at which the material is placed back into the trench.

Adjustable Sections

The front and rear sections can adjusted hydraulically to compensate for different terrain gradients.

Insulated Engine

Engine compartment reduces noise to comply with EU noise limit requirements.

Optional ROPS

In addition to being required in many countries, ROPS increases safety for the operator.

Oscillating Cabin

Hydraulically slides out to either side of the machine to increase visibility.

Control Panel

The controls are duplicated on both sides of the cabin for ease of operation on either side of the trench.

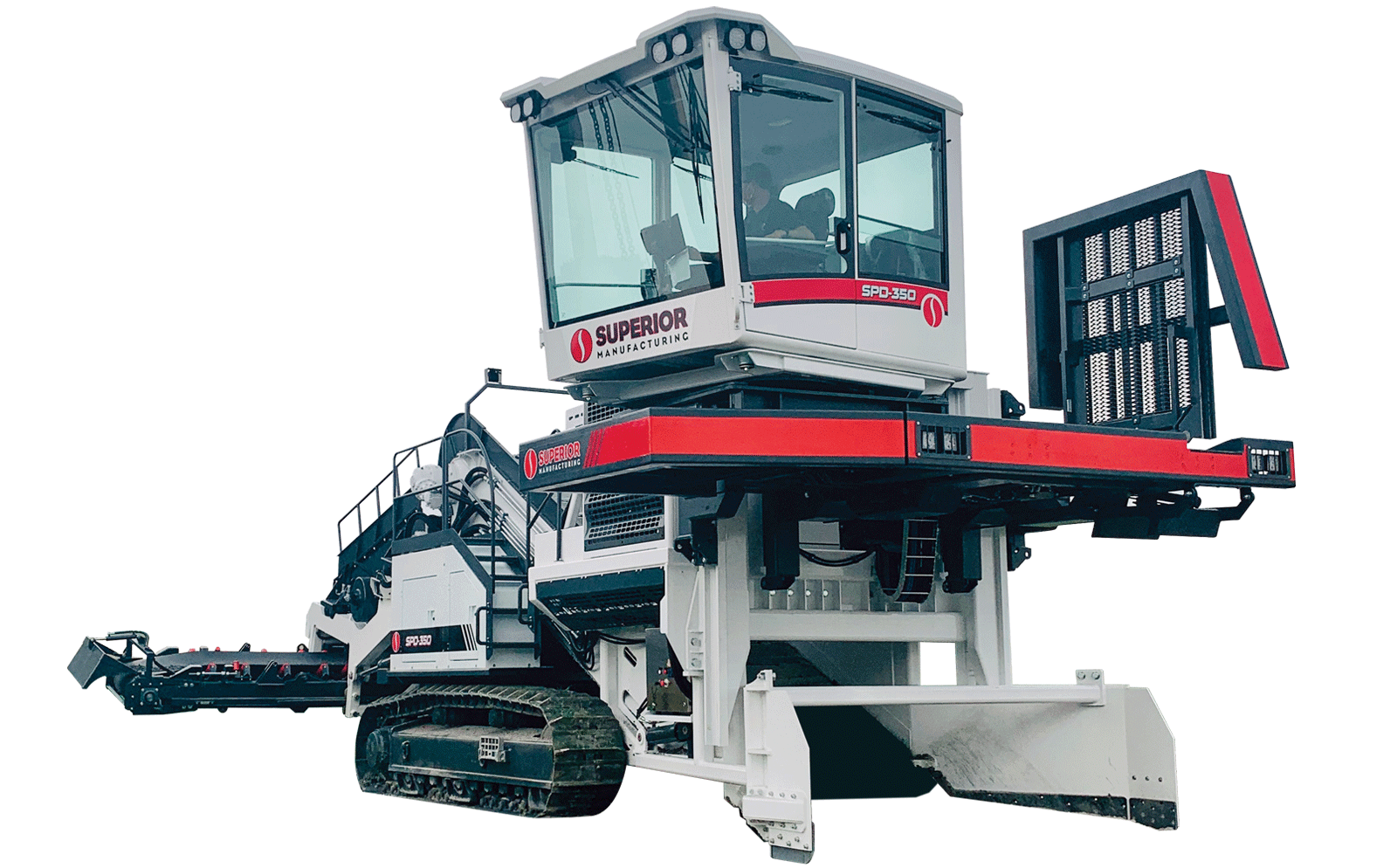

SP-350 HD

Features

Roll over the red circles to view features.

Reversible Conveyor

Can be used on either side of machine and folds into 3 parts for ease of shipping. A hydraulically-controlled dowel adjusts the angle and distance at which the material is placed back into the trench.

Camera Monitoring System

Three cameras to monitor the offside of the machine and the loading of material.

Insulated Engine

Engine compartment reduces noise to comply with EU noise limit requirements.

Optional ROPS

In addition to being required in many countries, ROPS increases safety for the operator.

Oscillating Cabin

Hydraulically slides out to either side of the machine to increase visibility.

Extended Undercarriage

The undercarriage is built for additional stability.